M Series Diesel Forklifts>>Description

- 2.5T

-

Forklift Show

-

INTRODUCTION TO MAXIMAL

The M series is the first generation forklifts, designed by the MAXIMAL engineering team. A world class design features advanced technologies and superior componentry as produced by competitive vendors the world over. The finished appearance with safety color design has attracted an audience in local and the world markets.

-

EREGONOMIC DESIGN

Larger low positioned steps on either side and large grab bar allows easy access-egress for the operator.

The large premium suspension safety seat provides operator comfort and better productivity in all applications.

Forward positioned hydraulic control and left hand directional travel levers are within easy reach of the operator. The large floor space with convenient positioned pedal arrangement permits optimum control and safe operation. The full rubber floor mat and synthetic mounted operator compartment reduces vibration and eliminates operator fatigue.

ROBUST WIDE VIEW MAST

Heavy I beam and C channel mast rails are positioned to create a wider forward view of the fork tips and the load. Large rollers roll more freely under load and side thrust rollers provide added lateral support especially in wide load applications. Both load rollers and thrust rollers are externally adjustable to maintain mast and carriage alignment and, reduce labor costs. Hydraulic hoses are positioned behind the rails for protection and enhance forward visibility through the mast.

-

HYDRAULIC SYESTEM COMPONENTS

Premium hydraulic hose, fittings and steel tubes are vital to operator safety and load handling. All hydraulic cylinders use premium seals eliminating leaks and pressure loss. Main lift cylinder has a lowering speed valve to avoid rapid decent should a pressure lose occur in the lifting system.

Fully adjustable steering wheel allows multiple operator sizes and added comfort. Power steering provides precise control and easy maneuverability in confined spaces reducing operator fatigue and stress.

-

COOLING SYSTEMS

An all aluminum radiator core provides constant engine coolant temperature control through faster heat dissipation. Combination engine coolant and transmission fluid radiator is designed for maximum air flow passing through the counterweight. A newly designed composite fan blade provides better air flow through the cooling system tunnel and creates less noise and distraction for the operator.

-

ELECTRICAL SYSTEM

The lighted instrument panel is conveniently positioned relative to the operator’s line of sight. The LCD display monitors the machine’s vital components and electrical systems including travel speed and operating time. The monitor with integrated diagnostic system provides easy service and lower maintenance costs. The advanced design wiring harness uses waterproof connectors and an enclosed multiunit fuse module for improved circuit security and reliability.

-

A CLEAN GREEN MACHINE

Latest technology LPG and Diesel engines have EPA tier 3 and EU stage IIIA rated engines certified to meet/exceed CARB emissions. These High performance engines use less fuel per operating hour and eliminate harmful emissions in the workplace.

Engine covers open to the rear allowing ample access to the engine compartment while the lift out floor plate provides easy access to the drive train components.

-

EFFICIENCY

MAXIMAL lift trucks are designed for the operator to be more productive And require less downtime for maintenance.

MAXIMAL value added lift trucks have earned a reputation for being tough, reliable and agile to handle more product with less operator effort in virtually every application.

-

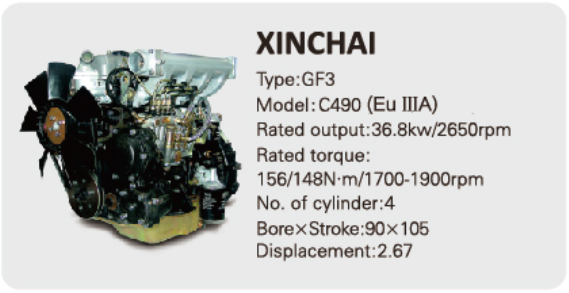

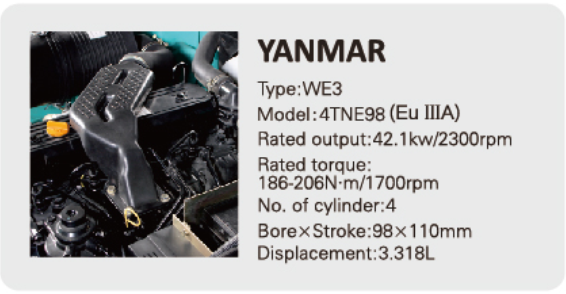

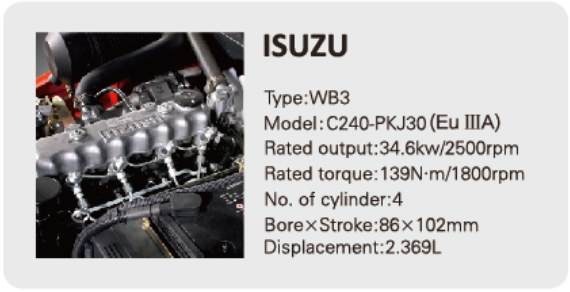

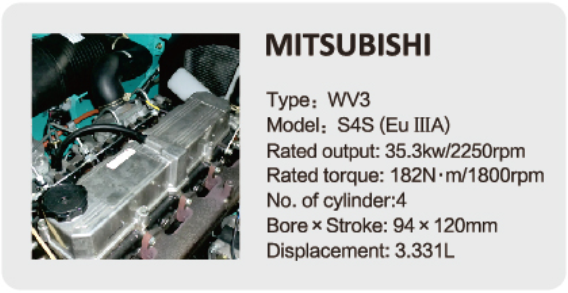

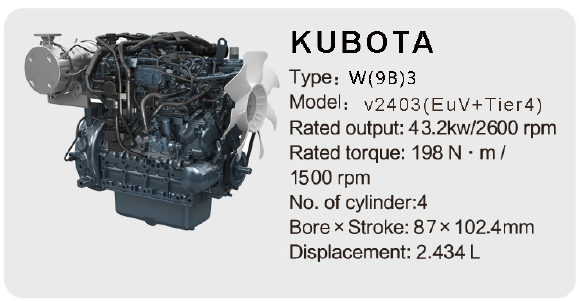

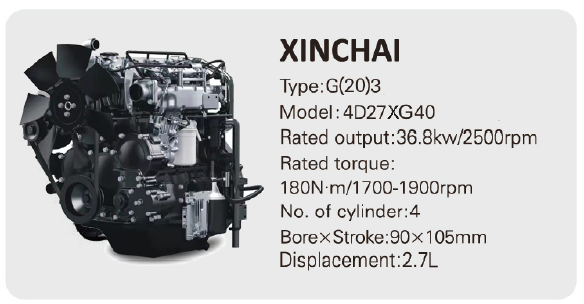

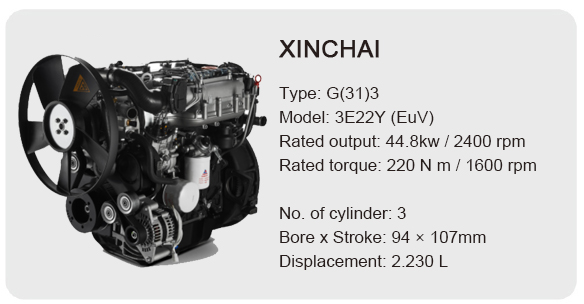

Engine

-

Forklift Specification

| General |

1 |

Model |

|

FD25T-M3WV3 |

FGL25T-M3WA3 |

| 2 |

Type |

|

Diesel |

Gasoline&LPG |

| 3 |

Optional type |

|

W(9)3/G(20)3/G(17)3/WE3/WB3/G(1)3/GK3/GF3 |

WH3 |

| 4 |

Rated capacity |

Kg |

2500 |

2500 |

| 5 |

Load chart |

mm |

500 |

500 |

| Characteristic & dimension |

6 |

Lift height |

mm |

3000 |

3000 |

| 7 |

Free lift height |

mm |

160 |

160 |

| 8 |

Fork size |

L×W×T |

mm |

1070×122×40 |

1070x122x40 |

| 9 |

Fork regulating range |

Min./Max. |

mm |

250/1040 |

250/1040 |

| 10 |

Mast tilt angle |

F/R |

Deg |

6°/12° |

6°/12° |

| 11 |

Front overhang |

mm |

475 |

475 |

| 12 |

Rear overhang |

mm |

517 |

517 |

| 13 |

Min. ground clearance(bottom of mast) |

mm |

125 |

125 |

| 14 |

Overall dimensions |

Length to face of fork(without fork) |

mm |

2545 |

2570 |

| 15 |

Overall width |

mm |

1150 |

1150 |

| 16 |

Mast lowered height |

mm |

2010 |

2010 |

| 17 |

Mast extended height(with backrest) |

mm |

4025 |

4025 |

| 18 |

Overhead guard height |

mm |

2145 |

2145 |

| 19 |

Turning radius(outside) |

mm |

2330 |

2330 |

| 20 |

Min. right angle stacking aisle width |

Pallet size a12=1000,b12=1200 |

mm |

4005 |

4005 |

| Pallet size a12=1200,b12=800 |

mm |

4205 |

4205 |

| Performance |

21 |

Speed |

Travel(Unladen) |

Km/h |

19 |

19 |

| 22 |

Lifting(Laden) |

mm/s |

510 |

520/570(WG3) |

| 23 |

Lowering(Laden) |

mm/s |

450 |

450 |

| 24 |

Max. drawbar pull |

KN |

16 |

16 |

| 25 |

Max. gradeability(Laden) |

% |

20 |

20 |

| Tyre |

26 |

Tyre |

Front |

|

7.00-12-12 PR |

7.00-12-12 PR |

| 27 |

Rear |

|

6.00-9-10 PR |

6.00-9-10 PR |

| 28 |

Tread |

Front |

mm |

970 |

970 |

| 29 |

Rear |

mm |

980 |

980 |

| 30 |

Wheelbase |

mm |

1600 |

1600 |

| Weight |

31 |

Self weight |

kg |

3640 |

3620/3590(WG3) |

| 32 |

Weight distribution |

Laden |

Front axle |

kg |

5480 |

5450/5440(WG3) |

| 33 |

Rear axle |

kg |

660 |

670/650(WG3) |

| 34 |

Unladen |

Front axle |

kg |

1470 |

1530/1520(WG3) |

| 35 |

Rear axle |

kg |

2170 |

2190/2170(WG3) |

| Power&transmission |

36 |

Battery |

Voltage/Capacity |

V/Ah |

12/90 |

12/60 |

| 37 |

Transmission |

Manufacture |

|

China |

China |

| 38 |

Type |

|

Powershift |

Powershift |

| 39 |

Stage |

F/R |

|

1/1 |

1/1 |

| 40 |

Operating pressure(for attachments) |

Mpa |

17.5 |

17.5 |

-

Mast Specification

| Type |

Model |

Max. fork height |

Overall height |

Free lift |

Front Overhang |

Tilt range |

Capacity |

| Lowered |

Extended |

Without backrest |

with backrest |

FWD |

BWD |

load capacity at 500mm |

| Without backrest |

with backrest |

2.5t |

Single tyre |

Double tyre |

| 2.5t |

2.5t |

2.5t |

2.5t |

2.5t |

| mm |

mm |

mm |

mm |

mm |

mm |

mm |

Deg |

Deg |

kg |

kg |

| 2-stage mast |

M330 |

3300 |

2160 |

3875 |

4290 |

160 |

160 |

465 |

6 |

12 |

2500 |

— |

| M350 |

3500 |

2260 |

4075 |

4490 |

160 |

160 |

465 |

6 |

12 |

2500 |

— |

| M370 |

3700 |

2360 |

4275 |

4690 |

160 |

160 |

465 |

6 |

6 |

2500 |

— |

| M400 |

4000 |

2560 |

4575 |

4990 |

160 |

160 |

465 |

6 |

6 |

2500 |

— |

| M425 |

4250 |

2685 |

4825 |

5240 |

160 |

160 |

465 |

6 |

6 |

2300 |

2500 |

| M450 |

4500 |

2810 |

5075 |

5490 |

160 |

160 |

465 |

6 |

6 |

2100 |

2400 |

| M500 |

5000 |

3060 |

5575 |

5990 |

160 |

160 |

465 |

6 |

6 |

1600 |

1900 |

| M550 |

5500 |

3360 |

6075 |

6490 |

160 |

160 |

465 |

3 |

6 |

1200 |

1700 |

| M600 |

6000 |

3610 |

6575 |

6990 |

160 |

160 |

465 |

3 |

6 |

900 |

1400 |

| Full free 2-stage mast |

FM300 |

3000 |

2010 |

3590 |

3990 |

1420 |

1020 |

480 |

6 |

12 |

2500 |

— |

| FM330 |

3300 |

2160 |

3890 |

4290 |

1570 |

1170 |

480 |

6 |

12 |

2500 |

— |

| FM350 |

3500 |

2260 |

4090 |

4490 |

1670 |

1270 |

480 |

6 |

6 |

2500 |

— |

| FM370 |

3700 |

2360 |

4290 |

4690 |

1770 |

1370 |

480 |

6 |

6 |

2500 |

— |

| FM400 |

4000 |

2560 |

4590 |

4990 |

1970 |

1570 |

480 |

6 |

6 |

2500 |

— |

| Full free 3-stage mast |

TFM435 |

4350 |

2010 |

4867 |

5340 |

1390 |

1020 |

485 |

6 |

6 |

2200 |

2400 |

| TFM450 |

4500 |

2060 |

5017 |

5490 |

1440 |

1070 |

485 |

6 |

6 |

2000 |

2300 |

| TFM480 |

4800 |

2160 |

5317 |

5790 |

1540 |

1170 |

485 |

6 |

6 |

1700 |

2000 |

| TFM500 |

5000 |

2260 |

5517 |

5990 |

1640 |

1270 |

485 |

6 |

6 |

1500 |

1800 |

| TFM540 |

5400 |

2385 |

5917 |

6390 |

1765 |

1395 |

485 |

3 |

6 |

1200 |

1600 |

| TFM600 |

6000 |

2610 |

6517 |

6990 |

1990 |

1620 |

485 |

3 |

6 |

800 |

1300 |

| TFM650 |

6500 |

2825 |

7000 |

7490 |

2200 |

1830 |

485 |

3 |

6 |

500 |

1000 |