M Series Gasoline&LPG Forklifts>>Description

- 5.0-7.0T

-

Forklift Show

Previous Product: none

-

INTRODUCTION TO MAXIMAL

Safety & Stability

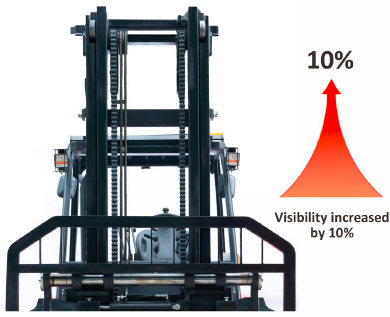

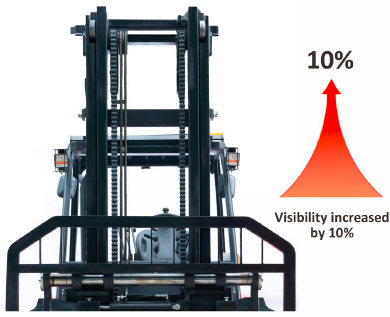

Mast and Mast Hydraulic(View improvement)

Replace the mechanical display with digital one, after entering the menu, the language types can be adjusted according to different customer requirements.

-

Well Formed Appearance

Hydraulic system improvement: The overall cleanliness of the hydraulic system is improved by wash machine.

-

Easily Maintenance

Hood opening angle

Use rough terrain truck hinge

Hood opening angle: from old 60 degrees to 80 degrees, better accessibility to maintenance

-

Electrical elements improvement

Waterproof plug-in, with ratings of Ip56

Plug-ins that reserve optional features are easy to install. (M series large tonnage many option not available i.e. handbrake alarm, seat belt sequence) while the new harness has reserved those functions. The corresponding electrical connector plug-ins are all updated to AMP plug-in, with better waterproofing.

Integrated electrical box, smaller in size than for the original M-Series, space-saving

The waterproof rating of the new electrical box is IP56 and the fire rating reaches V0.The new electrical box integrates the DH296 box function and has a driving safety device. Will improve vehicle safety performance(M-Series electrical boxes is without this device)

-

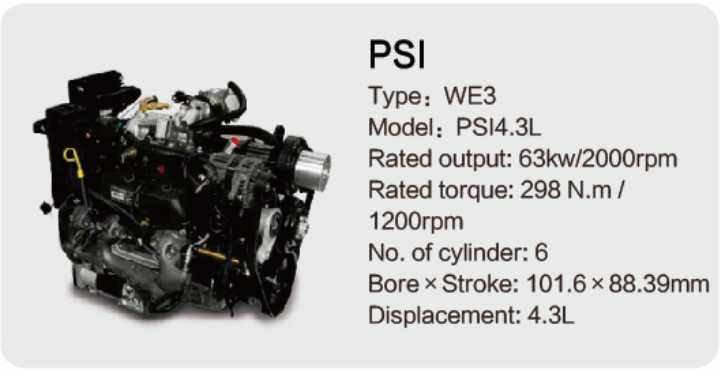

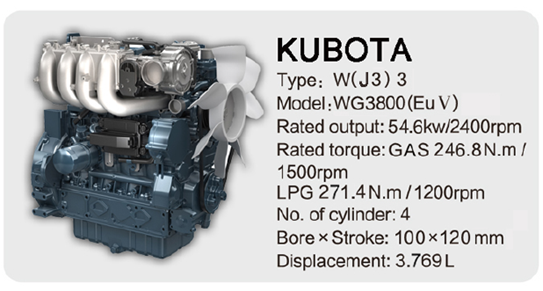

Engine

-

Forklift Specification

Distinguishing

mark |

1.1 |

Manufacturer |

|

Target |

Target |

| 1.2 |

Model designation |

|

FLTA50 |

FLTA70 |

| 1.3 |

Power: battery, diesel, LPG, electric mains |

|

LPG |

LPG |

| 1.4 |

Operation: manual, pedestrian, stand, seat, orderpicker |

|

SEAT |

SEAT |

| 1.5 |

Load capacity |

Q (kg) |

5000 |

7000 |

| 1.6 |

Load centre |

c (mm) |

600 |

600 |

| 1.8 |

Load distance |

x (mm) |

590 |

590 |

| 1.9 |

Wheelbase |

y (mm) |

2300 |

2300 |

| Weight |

2.1 |

Unladen weight |

kg |

8360 |

9650 |

| 2.2 |

Axle loading, laden front |

kg |

12090 |

14900 |

| |

Axle loading, laden rear |

|

1270 |

1750 |

| 2.3 |

Axle loading without load, front |

kg |

3840 |

4050 |

| |

Axle loading without load,rear |

|

4520 |

5600 |

| Tyres, chassis |

3.1 |

Tyres: L = pneumatic, V = cushion, SE = superelastic |

|

L |

L |

| 3.2 |

Tyre size, front |

|

8.25-15-14PR |

8.25-15-14PR |

| 3.3 |

Tyre size, rear |

|

8.25-15-14PR |

8.25-15-14PR |

| 3.5 |

Number of wheels, front/rear (X = driven) |

|

4X2 |

4x2 |

| 3.6 |

Track width, front |

b10 (mm) |

1489 |

1489 |

| 3.7 |

Track width, rear |

b11 (mm) |

1700 |

1700 |

| Dimensions |

4.1 |

Mast tilt, forward α/back β |

α /β (°) |

10/12 |

10/12 |

| 4.2 |

Height of mast, lowered |

h1 (mm) |

2500 |

2625 |

| 4.3 |

Free lift s |

h2 (mm) |

205 |

205 |

| 4.4 |

Lift height s |

h3 (mm) |

3000 |

3000 |

| 4.5 |

Height of mast, extended : |

h4 (mm) |

4425 |

4425 |

| 4.7 |

Height to top of overhead guard m |

h6 (mm) |

2450 |

2450 |

| 4.8 |

Seat height 8 |

h7 (mm) |

1400 |

1400 |

| 4.12 |

Towing coupling height |

h10 (mm) |

345 |

345 |

| 4.19 |

Overall length |

l1 (mm) |

4715 |

4830 |

| 4.20 |

Length to face of forks |

l2 (mm) |

3495 |

3610 |

| 4.21 |

Overall width, Std/Dual |

b1 (mm) |

2020 |

2020 |

| 4.22 |

Fork dimensions ISO2331 |

s/e/l (mm) |

65/150/1220 |

65/150/1220 |

| 4.23 |

Fork carriage to DIN 15173. Class, A/B |

|

ISO 4A |

ISO 4A |

| 4.24 |

Fork carriage width w |

b3 (mm) |

1845 |

1845 |

| 4.31 |

Ground clearance under mast, without load/with load |

m1 (mm) |

200 |

200 |

| 4.32 |

Ground clearance at centre of wheelbase |

m2 (mm) |

230 |

230 |

| 4.33 |

Load dimension b 12 x l 6 crossways |

b 12 x l 6 (mm) |

1000x1000 |

1000x1000 |

| 4.34 |

Aisle width with predetermimned load dimensions |

Ast (mm) |

5030 |

5150 |

| 4.34.1 |

Aisle width with pallets 1000mm x 1200mm crossways |

Ast (mm) |

5030 |

5150 |

| 4.34.2 |

Aisle width with pallets 800mm x 1200mm crossways |

Ast (mm) |

4830 |

4950 |

| 4.35 |

Outer turning radius |

Wa (mm) |

3250 |

3360 |

| 4.36 |

Internal turning radius |

b13 (mm) |

1105 |

1105 |

| |

Step height (from ground to running board) |

mm |

968 |

968 |

| |

Step height (between intermediate steps and floor) |

mm |

330 |

330 |

-

Mast Specification

| Type |

Model |

Max.

fork

height |

Overall Height |

| Lowered |

Extended |

| Without LBR |

With LBR |

| 5t |

7t |

5t |

7t |

5t |

7t |

| mm |

mm |

mm |

mm |

mm |

mm |

mm |

| 2LFL |

M300 |

3000 |

2500 |

2625 |

3900 |

4000 |

4370 |

4370 |

| M330 |

3300 |

2650 |

2775 |

4200 |

4300 |

4670 |

4670 |

| M350 |

3500 |

2750 |

2875 |

4400 |

4500 |

4870 |

4870 |

| M375 |

3750 |

2875 |

3000 |

4650 |

4750 |

5120 |

5120 |

| M400 |

4000 |

3050 |

3175 |

4900 |

5000 |

5370 |

5370 |

| M425 |

4250 |

3175 |

3300 |

5150 |

5250 |

5620 |

5620 |

| M450 |

4500 |

3300 |

3425 |

5475 |

5600 |

5925 |

5925 |

| M475 |

4750 |

3425 |

3550 |

5650 |

5750 |

6120 |

6120 |

| M500 |

5000 |

3550 |

3675 |

5900 |

6000 |

6370 |

6370 |

| M550 |

5500 |

3850 |

3975 |

6400 |

6500 |

6870 |

6870 |

| M600 |

6000 |

4100 |

4225 |

6900 |

7000 |

7370 |

7370 |

| 2FFL |

FM300 |

3000 |

2625 |

2625 |

4110 |

4110 |

4405 |

4405 |

| FM330 |

3300 |

2775 |

2775 |

4410 |

4410 |

4705 |

4705 |

| FM350 |

3500 |

2875 |

2875 |

4610 |

4610 |

4905 |

4905 |

| FM375 |

3750 |

3000 |

3000 |

4860 |

4860 |

5155 |

5155 |

| FM400 |

4000 |

3175 |

3175 |

5110 |

5110 |

5405 |

5405 |

| 3FFL |

TFM400 |

4000 |

2505 |

2505 |

5080 |

5080 |

5405 |

5405 |

| TFM435 |

4350 |

2630 |

2630 |

5430 |

5430 |

5755 |

5755 |

| TFM450 |

4500 |

2680 |

2680 |

5580 |

5580 |

5905 |

5905 |

| TFM480 |

4800 |

2780 |

2780 |

5880 |

5880 |

6205 |

6205 |

| TFM500 |

5000 |

2880 |

2880 |

6080 |

6080 |

6405 |

6405 |

| TFM540 |

5400 |

3005 |

3005 |

6480 |

6480 |

6805 |

6805 |

| TFM600 |

6000 |

3305 |

3305 |

7080 |

7080 |

7405 |

7405 |

| TFM650 |

6500 |

3530 |

3530 |

7580 |

7580 |

7905 |

7905 |

| Type |

Model |

Max.

fork

height |

Free Lift |

Load Distance |

Tilt range |

| Without LBR |

With LBR |

FWD |

BWD |

| mm |

mm |

mm |

mm |

Deg |

Deg |

| 2LFL |

M300 |

3000 |

205 |

205 |

590 |

10 |

12 |

| M330 |

3300 |

205 |

205 |

590 |

10 |

12 |

| M350 |

3500 |

205 |

205 |

590 |

10 |

12 |

| M375 |

3750 |

205 |

205 |

590 |

10 |

12 |

| M400 |

4000 |

205 |

205 |

590 |

10 |

12 |

| M425 |

4250 |

205 |

205 |

590 |

6 |

6 |

| M450 |

4500 |

205 |

205 |

590 |

6 |

6 |

| M475 |

4750 |

205 |

205 |

590 |

6 |

6 |

| M500 |

5000 |

205 |

205 |

590 |

6 |

6 |

| M550 |

5500 |

205 |

205 |

590 |

3 |

6 |

| M600 |

6000 |

205 |

205 |

590 |

3 |

6 |

| 2FFL |

FM300 |

3000 |

1555 |

1255 |

600 |

10 |

12 |

| FM330 |

3300 |

1705 |

1405 |

600 |

10 |

12 |

| FM350 |

3500 |

1805 |

1505 |

600 |

10 |

12 |

| FM375 |

3750 |

1930 |

1630 |

600 |

10 |

12 |

| FM400 |

4000 |

2105 |

1805 |

600 |

10 |

12 |

| 3FFL |

TFM400 |

4000 |

1460 |

1135 |

635 |

6 |

6 |

| TFM435 |

4350 |

1585 |

1260 |

635 |

6 |

6 |

| TFM450 |

4500 |

1635 |

1310 |

635 |

6 |

6 |

| TFM480 |

4800 |

1735 |

1410 |

635 |

6 |

6 |

| TFM500 |

5000 |

1835 |

1510 |

635 |

6 |

6 |

| TFM540 |

5400 |

1960 |

1635 |

635 |

3 |

6 |

| TFM600 |

6000 |

2260 |

1935 |

635 |

3 |

6 |

| TFM650 |

6500 |

2485 |

2160 |

635 |

3 |

6 |